Work Samples

Since beginning my journey in this field, my dedication to the work and motivation to grow have led me to exceptional projects and experiences. I’m grateful to be passionate about Materials Engineering, and am proud to share examples of my greatest work, from co-op, school, and personal projects.

Desktop Metal, Co-op

Redesigned Retort

3D metal printed parts at Desktop Metal were cracking and not performing well after going through the debinding and sintering process in a generic high-temperature furnace

Retorts create a controlled atmosphere within the furnace so that extreme heat treatments can occur and the parts can be sintered

I aimed to redesign the retort specifically for Desktop Metal’s 3D metal printed parts in their Ipsen-brand furnace

Considered factors such as materials, thermal properties, heat transfer properties, direction of air flow, size of printed parts, ease of use/transfer of parts. Specifically, I chose to make the retort out of a wrought material with a low carbon content, so that the material would have a tighter grain structure and higher ductility, which resulted in a greater resistance to thermal fatigue

Design was implemented at DM and the printed parts going through the debind and sintering process had increased mechanical properties

Siklus Jakarta, Engineering Capstone Project

Automated Refill System

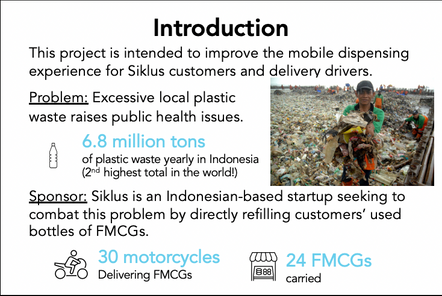

Indonesia is the 2nd largest plastic polluter in the world, due to dense populations, high plastic usage, and little proper waste management

Siklus Jakarta, an Indonesian-based company is aiming to reduce plastic polution through eliminating single-use plastic bags called sachets (household cleaning products are typically sold in these) and instead, delivering these products directly to the customer in their reusable bottles with a mobile apparatus (seen in picture) on the back of a motorcycle.

My capstone group worked to improve pain points of the current design through automation.

By using modified caps on the jerry cans with a rigid pipe allowing for an air inlet, the flow rates of the products being dispensed has significantly improved (from less than 1L/min to ~10L/min depending on the product). We also have load cells placed under each jerry can in the mobile apparatus (seen in picture) to monitor volume loss in order to charge the customer the correct amount.

The project was finished over the course of 6 months and was wrapped up in December of 2021.

More detailed information can be seen in the photos below.

Demand Management Institute, Co-op

Energy Efficiency Savings Calculator

Utility Companies in New Hampshire spend too much time and often make mistakes calculating savings

Aimed to create a streamlined savings calculation tool for the utility companies to simply enter known values for a savings output

Considered individual measures and corresponding savings calculations for Building Shell, Compressed Air, Hot Water, HVAC, and Refrigeration; used macros and advanced Excel functions to “code” the spreadsheet; used over 30+ spreadsheet tabs

Implemented at Eversource NH, Liberty, and National Grid NH

Smaller Projects

Study Abroad

During the summer of 2019, I went on a month long study abroad trip to Belize with a focus on Archaeological and Ceramic Materials. The following highlights a few of my favorite materials activities we did while in Belize.

Brick Making

Brick Making in Belize is a highly uncommon procedure - typically, bricks are imported or not used at all

The only brick maker in the country taught my study abroad group how he makes the bricks

In this more primitive approach, we combined clay with sawdust and tossed it into a machine that combines it with water and shapes it. We then used fishing wire to cut the bricks into the required sizes. We left the bricks out in the sun to dry, then fired a homemade kiln to 900 degrees Celsius and placed the bricks in for a full day.

Despite this somewhat primitive approach, we created incredibly strong and durable bricks (they don't fracture until 25,000 psi, almost 12x that of a typical kiln-fired brick)

Bamboo Cutting Board

Bamboo furniture pieces only use very specific pieces of the bamboo, leaving lots of waste leftover

We used these leftover pieces and parts from naturally fallen trees to create cutting boards by cutting the pieces into strips. The bamboo is then pressure-steamed (the process of carbonization) to free it of bugs; we also used this process to create different shades of color by carbonizing it for longer or shorter time periods. These strips are then laminated into sheets with glue and heat and smoothed down with sandpaper.

The process was incredibly rewarding and was my first time making anything with bamboo! Here's my (used) cutting board in my apartment!